“All in one nail gun” – when you read this word set, it means a nail gun that can be used in multiple jobs. For example, you can use a nail gun in framing, finishing, or roofing projects.

In reality, all in one nail guns don’t exist. Because there are some technical limitations like nail size variations, firing mechanism, etc. We have specialized nail guns for different projects like framing nailers, brad nailers, finish nailers, etc.

Though a nail gun is a versatile tool, they are not that much versatile to be applied to multiple tasks. Here are other reasons to not have any existence of all in one nail guns. We will discuss it here.

The Concept of an All in One Nail Gun

An all in one nail gun is a hypothetical tool that woodworkers can use in various projects like framing, finishing, brad nailing, roofing, and more.

It means you will use only one nail gun to establish multiple projects. It indicates you don’t need to keep multiple nail guns in your workshop to do multiple tasks.

Above all, you just need to keep only one nail gun to complete all projects. It eliminates the need for multiple nail guns.

Why All in One Nailers Aren’t Feasible

1. Technical Limitations

Different projects need different nail gauges and lengths. For example, framing tasks need large nails, and brad nailers use smaller nails to do the jobs.

As a result, a single tool can’t seamlessly accommodate this range.

2. Firing Mechanisms

Different nail guns use specific firing mechanisms like coil or strip mechanisms, based on the job. For example, Roofing nailers rely on coils for high capacity.

In contrast, finish nailers prefer strip designs for precision. So, it is quite impossible to have different firing mechanisms in one tool.

3. Ergonomic Challenges

Just imagine a nail gun with multiple capabilities that balance the size, weight, and usability.

It would be ergonomically challenging to handle framing and finish tasks simultaneously. It will be too heavy to carry.

4. Cost

Suppose, you have found a nail gun with multiple capabilities. But it will be more expensive than specialized nailers.

Challenges in Creating an All in One Nailer

Creating such a multiple nailer gun is challenging. There are several reasons behind the challenges.

Here are the challenges:

Design Complexity

Building a nail gun that works with various nail gauges, lengths, and angles requires a planned engineering.

Each type of nail gun has unique operational requirements. Combining these functionalities into a single tool makes it heavier and more prone to mechanical issues.

Power Source

Different nail guns use distinct power sources. For example, pneumatic nail guns use air compressors, cordless versions use batteries, gas powered versions come with gas cartridges.

Combining these options into a single device is quite impossible. Users will face challenges while needing an exact power source to run them.

Weight & Bulky

If you pour all in one feature in a nail gun, it will become too heavy and bulky. Users mainly demand ergonomic and portable nail guns for long time use ensuring no hand fatigue issues.

Lack of User Friendliness

Users might get confused about multiple features in one nailing tool. Often they trigger a wrong setting while using and the tool may malfunction.

Compatibility Issues

Standard nailers are built for specific nail sizes and types. In a specific nail gun using different sizes of nails is a nightmare yet. Creating a universal size of nail loading system for an all in one device would be tough.

Safety Concerns

Incorporating multiple functions in a single tool requires additional safety features. It might be challenging for the manufacturers to ensure strict industry safety standards.

Overall Performance

An all in one nailer might not perform effectively as well as specialized tools in specific jobs. A specialized nail gun for a specific project delivers the best output.

Whereas, this hypothetical nail gun often lacks precision, smoothness, and professional result.

Durability

Additional features in a gun nailer enhance the number of moving parts. Moreover, it will increase potential points of failure. Users will face difficulties while servicing a device that has more complex mechanisms.

Alternatives to an All in One Nailer

Fortunately, there are some practical alternatives that can fulfill the multiple nailing needs just for the time being.

Multiple Tool Kits

You can invest in a nail gun kit with multiple tools. For example, a kit might include a framing nailer for heavy-duty construction, a finish nailer for cabinetry or baseboards, and a brad nailer for precision and delicate tasks.

Moreover, staplers for upholstery or fastening thin materials. These multiple nail gun tool kits allow users to switch between tools without compromising performance. It also ensures each job is done with the proper equipment.

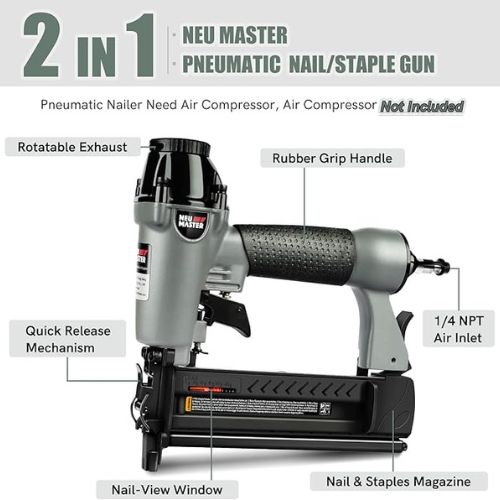

Convertibility

Some models of nail guns offer versatility like dual-mode brad or finish nailers. Some nail guns come with adjustable settings.

For example, adjustable depth control and interchangeable magazines. This example does not show 100% versatility. They just provide some flexibility for the users.

Specialized Tools or Nail Guns

Instead of all in one nailer, users wisely choose specialized nail guns for specific uses. For example, Roofing nailers for attaching roof shingles, 15 degree coil siding nailers for fencing and siding, and Pin nailers for delicate woodworking or craft projects.

Keeping more than two or three specialized tools on your job site ensures high performance and precision for specific jobs.

Dual Mode Nail Guns

Dual mode nailer guns shoot different gauges of nails within a limited range. They are not versatile as a hypothetical all in one featured nail gun. But they keep a balance between functionality and practicality.

Air Compressors to Support Multi Air Nailers

In the case of pneumatic or air nailers, a single air compressor can support multiple nailers at one time. Users can connect different types of air nail guns to the same air compressor.

Renting Nail Guns

Users who don’t need nail guns all the time can rent or borrow tools. It is a cost effective alternative. They don’t need to purchase multiple tools for multiple jobs.

Combining the Nailers with Other Tools

For example, pairing an 18 gauge brad nail gun with a staple gun or using a screw gun with a framing nail gun offers versatility without sacrificing performance.

Sometimes combination of tools can achieve the same results as an all in one nailer gun.

Could Future Technology Make All in One Nailer Guns Possible?

All in one featured nail gun is a dream for professionals and DIY enthusiasts. They dream of advancements in several areas of technology that will pave the way.

Advanced Materials

Materials like carbon fiber composites or advanced alloys could reduce the heavy and bulkiness of the tools. These materials may ensure durability and eliminate ergonomics issues.

Adaptive Firing

Innovations like smart actuators or programmable firing systems could enable a nail gun to adjust its firing mechanism.

This advanced technology will allow a single tool to handle delicate trimming to heavy-duty framing tasks.

AI Driven Functionality

Artificial intelligence could play a significant role in creating an all-in-one featured nailer gun. This system could automatically detect the material type, nail type, and applications.

Moreover, adjusting settings like pressure, angle, and depth for smooth performance.

Nanotechnology

The internal mechanism of nail guns could be revolutionized by nanotechnology. It helps the manufacturers make parts smaller, more efficient, and less prone to wear.

Enable the tool with both versatility and durability with compactness.

IoT Connectivity

IoT means the integration of (Internet of Things) technology. Users can connect their nail guns with smartphones or other smart devices.

Users could modify settings, monitor performance, and receive maintenance alerts directly. This will make them more user-friendly.

Interchangeable Components

In the near future, we may see modular designs with interchangeable magazines, nozzles, or firing mechanisms.

It means you can change the components quickly to accommodate different projects. You will be able to switch the configurations fast and easily.

Efficient Power Source

Soon, we may see nail guns that contain versatile power options.

For example, a pneumatic nail gun will have an air compressor connection system at the tail of the tool, and at the same, it will have a battery inserting area.

Advanced Safety System

Multifunctional tools come with multiple safety concerns. Sensor technology could enable the development of integrated safety features, like automatic shutoff when the tool is not in use.

Moreover, augmented trigger controls or proximity sensors can eliminate accidental nail firing.

How to Maximize Efficiency Without an All in One Tool?

You don’t need to be worried if you don’t have a multifunctional tool. You need to determine the way to enhance your work efficiency with other tools like specialized nail guns.

Here we will learn some key strategies to maximize our efficiency without an all in one nailer:

- Invest in the Right Tools.

- You can grab nail gun kits with multiple tools for different applications.

- Storage your nail guns and other accessories for easy and quick access.

- Maintain your nail guns and other tool kits regularly. Oil your pneumatic nail guns daily.

- Establish effective nail gun work procedures before starting a project. For example, list the tools and nails you will need.

- Set up your workspace.

- Use tool belts to keep essential items close.

- Use quick connect couplers for air nailers.

- Enhance your or your workers’ skills with different nail gun training.

- Abide by the manufacturer’s instructions properly.

Challenges for Manufacturers

Manufacturers often face some unavoidable challenges while developing an all in one nailer gun. Some of them are described below:

R&D Costs

Designing this kind of multi-purpose tool needs extensive research, repetitive testing, and innovation. It increases the cost of production.

Setting High Selling Price

Due to the high cost of production, manufacturers are compelled to set high prices. Because they won’t produce or sell a product at a loss. They need profit.

Market Considerations

If manufacturers set high prices, then nail gun users will not purchase these multifunctional tools. Moreover, users are habituated to purchasing specialized nail guns for specific projects.

Balancing Design

Combining core features like universal nail compatibility, multiple nail magazine systems, versatile power sources, etc. may lead the manufacturers to imbalance design.

It will increase the tool’s weight and eliminate handiness.

Insecurity in Providing Guarantee

Due to multiple functions, manufacturers can’t ensure a long term guarantee of smooth operation.

What is my Prophecy?

An all in one nail gun can be a reality in the future, as technology advances. However, it will be quite difficult and challenging for the manufacturers.

If it happens, users need to maintain it properly to keep it in tip-top shape. But we have to keep in mind that, the future is always unpredictable. We don’t know what will happen tomorrow.

Hence, nowadays, relying on specialized nail guns for specific jobs will be a wise decision rather than waiting for all in one nailer.

FAQs

1. Do all nails fit all nail guns?

Ans: No, not all nails fit all nail guns. Each category of nail gun is designed for specific nail types and sizes. For example, an 18 gauge brad nail gun can’t hold larger nails like framing nailers.

Always check your nail gun’s specifications to ensure the right nail compatibility.

2. Do all framing nail guns use the same nails?

Ans: No, not all framing nail guns use the same nails. Framing nailers are designed for specific nail types, sizes, and angles. Common angles are 21°, 28°, and 30-34°. The nails should match the angle of the gun.

3. Can I use screws instead of brad nails?

Ans: Yes, you can use screws instead of brad nails. However, it depends on the project.

4. What’s the biggest challenge in creating an all in one nail gun?

Ans: The biggest challenge in creating an all in one nail gun is balancing versatility with performance. Then comes nail compatibility. Because different nail sizes are compatible with different nailers.