If you work on construction or DIY projects, you have likely used framing nail guns, but have you wondered what a clipped-head framing nail gun is?

A clipped-head framing nailer is a tool that can help get the job done faster and more efficiently. Professionals love this tool because it is compact and powerful. Whether framing a house, building a deck, or doing some repairs, clipped-head nail guns provide speed and reliability.

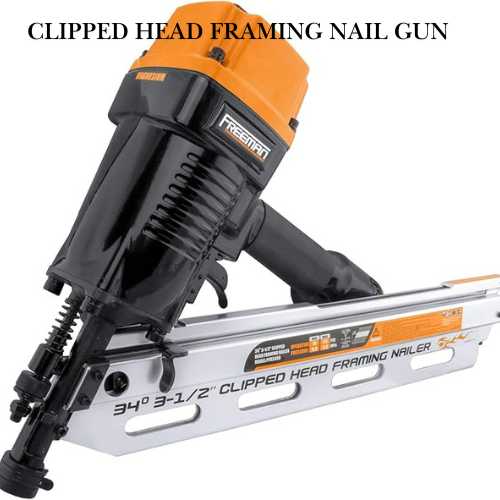

What is a Clipped Head Framing Nail Gun?

Definition of a Clipped Head Framing Nail Gun

A clipped-head framing nail gun is a tool that drives nails with a “clipped” or “D”-shaped head. It is more compact and efficient than a round or full-head framing nail gun. Clipped-head nail guns are commonly used for framing structures because they give a secured hold with less material used.

Design of Clipped Head Framing Nails

The head of these nails is clipped. This design allows for a higher magazine capacity because the nails are shorter and fit well in the magazine. The clipped head design also makes the nail gun suitable for large framing projects.

Types of Clipped Head Framing Nail Guns

Clipped head-framing nail guns are available in both pneumatic (air-powered) and cordless (battery-powered) models. Pneumatic models are more common and cost-effective. Cordless models provide portability but at a higher price. We’ll know more about this later in this article.

Difference Between Full Head and Clipped Head Framing Nails

Full head nails have a round, larger head. They provide more holding power, especially for heavy applications. On the other hand, clipped head-framing nails have a smaller head design. They are more efficient and are usually used for lighter framing tasks. Stay tuned to read more about them.

Features of a Clipped Head Framing Nail Gun

High-Capacity Magazine

A clipped head framing nail gun’s magazine can hold more nails than a typical framing nail gun. It reduces reload frequency by its increased holding power. This is ideal for long projects that need continuous nailing.

Adjustable Depth Settings

Many models of clipped head-framing nail guns have adjustable depth controls. These settings let the users customize the depth they want the nails to drive into.

Pneumatic, Cordless, and Gas-Powered Options

Clipped head framing nail guns are available in various power sources such as pneumatic, cordless, and gas-powered. We’ll know more about it later.

Lightweight and Ergonomic Construction

Clipped head framing nail guns are designed with comfort in mind. They feature lightweight bodies and ergonomic handles. These features help to reduce fatigue during operation.

Anti-Jamming Mechanism

Modern models of clipped head-framing nail guns have anti-jam features to minimize misfires. This also provides smoother operation and maximum productivity.

Durable Build for Heavy-Duty Use

Clipped head framing nail guns are so durable that they can handle demanding construction tasks. They are made of high-quality materials that enhance longevity and performance.

Safety Features

The clipped head-framing nail guns have safety features like trigger locks and dry fire systems. These mechanisms protect users from accidents.

Pros and Cons of a Clipped Head Nail Gun

| Pros | Cons |

| Higher Magazine Capacity: Clipped head framing nail guns hold more nails in the magazine due to their compact nail design | Building Code Restrictions: Some regions have made the use of roundhead nails mandatory for structural integrity. This limits the use of clipped head framing nails inapplicable in certain areas. |

| Compact Design for Tight Spaces: The slimmer design makes these nail guns ideal for operating in tight areas | Reduced Holding Power: Clipped head framing nails may provide slightly less holding power compared to round head nails. |

| Lighter Weight: Many clipped head framing nail guns are lighter than round head versions. | Limited Availability of Clipped Head Framing Nails: Clipped head framing nails are not as widely available as round head nails. |

| Faster Nailing: Their fast speed of nailing can save significant time on large-scale projects. | Compatibility Issues with Other Nail Guns: Clipped head framing nails are often incompatible with round-head nail guns. |

| Cost-Effective Nails: Clipped head framing nails take less material to make so they are less costly than round head nails. | Potential for Nail Jams: Some models of clipped head framing nail guns may have more frequent jamming. |

| Precision Nailing: Clipped head framing nail guns are designed for precise nail placement. | Perception of Weaker Grip: Clipped head framing nails sometimes have less grip. |

Types of Clipped Head Framing Nail Guns

Pneumatic Clipped Head

The pneumatic models of clipped head-framing nail guns are powered by air compressors. These provide force and consistency to the worker while doing professional framing work.

Cordless/Battery-Powered Clipped Head

Cordless models are more convenient because they eliminate the need for air hoses. The main feature of the cordless models is their portability. They are suitable for remote job sites or areas without access to power.

Gas-Powered Clipped Head

Gas-Powere clipped head-framing nail guns are also portable. They provide power because they use small fuel cells. They’re versatile and can be used outdoors and for high-volume tasks.

Electric Clipped Head

Electric models of clipped head-framing nail guns work by plugging into an electrical outlet or with rechargeable batteries. They are less common but great for DIYers.

Compact Clipped Head

These are the smaller versions of a clipped head-framing nail gun. They are suitable for lightweight tasks and smaller spaces. They may have less magazine capacity but are great in precision.

Dual-Powered Hybrid Clipped

Hybrid models of clipped head-framing nail guns have both pneumatic and battery options. These provide flexibility and the users can switch power sources depending on the task’s demands.

Nail Types Compatible with Clipped Head Framing Nail Guns

Clipped Head Framing Nails

Clipped head-framing nails are specifically designed to be used with clipped head-framing nail guns. These nails feature a “clipped” or “D” shaped head and they fit more compactly in the magazine so that the tool can hold more nails. The clipped head framing nails are ideal for general framing tasks, like securing studs, beams, and sheathing.

Full Round Head Nails

Some clipped head framing nail guns also support full round head nails. These nails have a larger, rounder head and provide greater holding power than clipped head-framing nails. They are suitable for more heavy-duty tasks. However, using full-round nails may reduce the magazine capacity of the tool.

Smooth Shank Nails

Smooth shank nails are those that have smooth surfaces without any ridges They are commonly used with clipped head framing nail guns. These nails are ideal for softwoods and general framing purposes.

Ring Shank Nails

Ring shank nails are designed with rings along the shaft and provide superior holding power compared to smooth shank nails. These nails are ideal for clipped head-framing nail guns. They can be used for tasks that require a more secure hold, such as outdoor framing.

Screw Shank Nails

Similar to ring shank nails, screw shank nails have spiral threads. They provide better holding power. These nails are highly effective in high-stress areas. Also, they are suitable to be used with clipped head-framing nail guns

Galvanized Nails

Galvanized nails are coated with a layer of zinc to prevent rust and corrosion. They are perfect for outdoor or moisture-prone environments. Clipped head framing nail guns can use galvanized nails.

Coated Nails (Tungsten or Epoxy Coated)

Coated nails, such as those with a coating of tungsten or epoxy, provide additional protection against rust. This feature improves the nail’s resistance to the material. These nails are compatible with clipped head-framing nail guns and are often used in harsh environments.

Top Clipped Head Framing Nail Gun Models and Their Specifications

| Brand | Popular Models | Power Source | Weight | Price Range | Magazine Capacity | Nail Size | Ergonomic |

| Paslode | Paslode Impulse 7500, CF325XP | Cordless | 7.2 lbs | Around $150 | Approx. 50 nails per load | 2 to 3.5 inches | Ergonomic design, rubber grip |

| DeWalt | DCN692B, DWF83PL | Pneumatic | 8 lbs | Around $300 | Approx. 60 nails per load | 2 to 3.5 inches | Easy handling, lightweight |

| Hitachi | NR90AES1, NR65AK | Pneumatic | 6.4 lbs | $150 – $200 | Approx. 60 nails per load | 2 to 3.5 inches | Well-balanced, ergonomic design |

| Bostitch | N80CB-1 | Pneumatic | 8.84 lbs | Around $400 | 300 nails per load | 2 to 3.5 inches | Lightweight, anti-vibration features |

| Makita | XNB02Z | Cordless | 8.12 lbs | Around $350 | Upto 110 nails per load | 2 to 3.5 inches | Ergonomically designed with soft grips |

| Senco | SFN30 | Pneumatic | 3.6 lbs | Around $300 | 104 nails per load | 1 to 2 inches | Well-designed for less fatigue, rubberized handles |

| Porter Cable | FR350B | Pneumatic | 6 – 7 lbs | Around $200 | 60 nails per load | 2 to 3.5 inches | Comfortable and balanced design |

How Does a Clipped Head Framing Nail Gun Work?

Pneumatic Power Mechanism

Most clipped head-framing nail guns use compressed air to drive nails. The air pressure propels the nail with force and the nail penetrates into the materials.

Sequential or Bump Firing Modes

Most clipped head-framing nail guns have different firing modes built into them. Users can switch between sequential firing (one nail at a time) and bump firing (rapid nailing). This flexibility helps in precision tasks and speed-intensive jobs.

Clipped Head Framing Nail Compatibility

Clipped head-framing nail guns are specifically designed to support clipped head-framing nails, which have a “D” shape. It aids in compact storage and efficient nail feeding into the magazine.

Trigger and Safety Mechanisms

The gun possesses a trigger mechanism and they often have a safety tip that must be pressed against the surface before firing. This reduces the risk of accidental discharge.

Depth Adjustment Settings

Built-in depth settings in clipped head framing nail guns help users control how deep the nails are driven depending on the material.

Magazine Feed System

Clipped head-framing nail guns have a spring-fed magazine. This magazine pushes the clipped headnails into the firing position whenever it is empty. This ensures continuous operation.

Air Hose or Cordless Battery Connection

Pneumatic models connect to an air compressor, while cordless versions rely on rechargeable batteries. Both deliver consistent nailing power for construction work.

How to Load a Clipped Head Framing Nailer

Check Compatibility

Always confirm that the clipped headnails you are using are suitable for your specific nail gun model. Using the wrong nails can cause jamming or misfiring.

Open the Magazine

Slide open the nail gun’s magazine according to the manufacturer’s instructions. This step is important for accessing the nail chamber without damaging the tool.

Insert Nails Properly

Align the clipped headnails in the magazine so that the heads face in the correct direction. Incorrect placement may cause feeding issues during operation.

Secure the Nails

While placing the nails inside the magazine, make sure they are seated firmly.

Close the Magazine

After the nails are properly loaded, close the magazine securely. This prevents nails from falling out during use.

Test the Loading

Once loaded, perform a test shot to confirm that the tool is functioning properly. This prevents problems when you start the actual work.

Applications of a Clipped Head Framing Gun Nailer

Residential Framing Projects

Clipped head framing nail guns are widely used for constructing walls, roofs, and floors in homes. Their efficiency speeds up residential building making.

Commercial Construction Work

These tools are also essential in commercial projects, like office buildings and warehouses.

Deck and Fence Building

Clipped head-framing nail guns are ideal for securing wooden planks or beams. Their precision ensures clean, durable joints.

Remodeling and Renovation

During renovation projects, you need to frame walls or install beams. Clipped head-framing nail guns make these tasks quick. Their lightweight design aids in mobility.

Sheathing and Subfloor Installation

They are commonly used to attach plywood sheathing and subfloor panels.

How to Choose the Right Clipped Head Framing Nailer Gun

Consider Your Project Needs

Research the type of projects you’ll be handling, such as framing or decking. Choose a nail gun with features suitable for your tasks.

Power Source Preference

Decide between pneumatic, cordless, or gas-powered options based on your work environment. Pneumatic models provide power, while cordless are portable.

Nail Compatibility

Ensure the nail gun supports the type and size of nails your task needs. Check building codes if round head nails are made compulsory in your area.

Weight and Ergonomics

Opt for a lightweight and ergonomic design for comfortable use during long hours.

Depth Adjustment and Firing Modes

Look for tools with adjustable depth settings and dual firing modes. These features help in precision and efficiency.

Brand Reputation and Warranty

Choose a reliable brand with positive reviews and a good warranty.

Clipped vs Full Head Nails

The primary difference between a clipped head and full headnails is the shape of the nail’s head. A clipped head nail has a smaller, “D” or “clipped” shape. This shape makes more nails to be loaded into the magazine possible, improves efficiency. On the other hand, full-head nails have a larger, rounder head, which provides superior holding power.

While full headnails are often preferred to be used for structural framing, clipped headnails are commonly used in non-structural framing in areas where speed is required.

Important Facts about Clipped Head Framing Nailers

| Fact | Explanation |

| Full Head vs. Clipped Head | Full-head nails have a larger head for more holding power, while clipped headnails are more compact and affordable. |

| Advantages of Clipped Head Nails | Higher magazine capacity, faster reloads, and lower costs. |

| Common Problems | Nail jamming, air pressure issues, and worn-out parts. |

| Cost Range | Prices for clipped head-framing nail guns range from $100 to $500. |

| Cordless vs. Pneumatic | Cordless models are more expensive but offer portability, Pneumatic models are cheaper but need an air compressor. |

| Best Practices for Loading | Ensure nails are properly aligned in the magazine to avoid jamming and misfiring. |

| Maintenance | Regular inspection, cleaning, and lubrication are essential. |

| Popular Brands | Leading brands include Paslode, DeWalt, Hitachi, Bostitch, and Makita. |

| Magazine Capacity | Clipped head framing nail guns have safety mechanisms such as a trigger lock and depth adjustment to prevent accidents. |

| Nail Strength | Full headnails have greater holding power than clipped headnails. |

| Clipped Head Nail Design | Clipped headnails have a “D” shape. |

Best Practices for Operating This Tool

Use Compatible Nails

Always use nails designed for your specific nail gun model.

Adjust Firing Depth

Customize the depth setting to match the material and project requirements.

Test Before Starting

Perform a few test shots on scrap material to ensure the gun is functioning correctly.

Maintain a Clean Work Area

Remove obstacles from your workspace to prevent accidents.

Hold the Gun Firmly

Keep a steady grip and press the safety tip against the surface before firing.

Tips for Safe and Efficient Use of This Nail Gun

Always Wear Proper Safety Gear

When using a clipped head framing nail gun, it’s important to wear personal protective equipment (PPE) including safety glasses, hearing protection, and gloves.

Check for Proper Nail Placement Before Firing

Ensure that nails are properly placed in the magazine before using the nail gun. Misaligned nails can cause jams.

Use the Correct Air Pressure or Battery Power

Always check the manufacturer’s recommended air pressure settings (for pneumatic models) and make sure the battery is fully charged (for cordless models).

Always Engage the Safety Mechanism

Before loading nails or adjusting the tool, ensure the safety mechanism (e.g., trigger lock) is engaged to prevent accidental firing.

Maintenance and Troubleshooting for Clipped Head Framing Nail Guns

Regular Cleaning to Prevent Jams

Keeping your clipped head framing nail gun clean is essential. It helps to prevent jams and ensure smooth operation. Dust, dirt, and debris can accumulate in the tool and cause misfires.

Lubrication for Optimal Performance

Lubrication is necessary to keep the internal components of the nail gun-running. Apply a small amount of pneumatic oil to the tool’s moving parts as recommended by the manufacturer.

Inspecting for Worn or Damaged Parts

Periodically inspect the moving parts and safety mechanisms for signs of damage or wear and repair if needed.

Clearing Jams Quickly and Safely

Jamming is a common issue with nail guns. This happens if nails are misaligned or if there is a build-up of debris. Always turn off the tool and disconnect the air supply or remove the battery before clearing a jam.

Storing the Tool Properly

Proper storage is vital to extend the life of your clipped head-framing nail gun. After use, store the tool in a dry, clean place to prevent rust and damage.

FAQs

1. Are clipped-head nails good for framing?

Ans: Yes, clipped-head nails are commonly used for framing in construction projects. Their compact, clipped design has higher magazine capacity in framing nail guns and as a result, it reduces the frequency of reloading and improves overall productivity.

2. What is the difference between a clipped head and full headnails?

Ans: The main difference between a clipped head and a full head is the shape of the nail’s head. A clipped headnail has a “D” or “clipped” shape and shape.

3. What is a clipped-head framing nail?

Ans: A clipped-head framing nail is a type of nail used in construction for framing. It has a smaller, clipped head. These nails are designed for fastening wood and other materials in structural and non-structural framing applications.

4. Are clipped-head nails stronger than full-head nails?

Ans: No, full-head nails are generally stronger than clipped-head nails. The larger round head of a full-head nail provides better-holding power compared to the smaller clipped head.

5. Can clipped-head nails be used for all types of framing?

Ans: Clipped-head nails can be used for most framing projects, but they are not always suitable for every project. Some building codes may restrict their use for structural framing because of their low holding power.

6. Do clipped head nails meet code?

Ans: Many areas allow clipped-head nails for non-structural framing, others may require full-head nails because of their greater holding capacity. Always check local building codes and regulations when using clipped-head nails in construction projects.

7. Can clipped-head framing nail guns be used with full-head nails?

Ans: In most cases, clipped-head framing nail guns can be used with full-head nails. Sometimes there are some limitations. Full-head nails may not fit as easily in the magazine of a clipped head-framing nail gun and can reduce the effectiveness of the tool. So, always check the manufacturer’s guidelines to ensure compatibility with full-head nails.

8. Are clipped-head nails rust-resistant?

Ans: Many clipped-head nails are galvanized or coated with other rust-resistant materials to prevent corrosion.

9. What should I do if my clipped-head framing nail gun jams?

Ans: If your clipped-head framing nail gun jams, first ensure that the air supply is turned off (for pneumatic models) or the battery is removed (for cordless models). Next, clear the jam and carefully remove any stuck nails or debris. Always follow the manufacturer’s instructions for safe jam clearance.