A nail is a thin, pointed piece made from metal or other materials, commonly used to fasten materials together. Without nails, a nail gun is nothing. Nails are synonymous with nail guns.

If you plan to use nail guns in a project, the most important factor is choosing the right nail size. The wrong nail size will create various problems. Every nail gun user should know nail gun nail sizes to complete their project successfully.

Why Nail Gun Nails Sizes Matter in Nail Gun Projects

Some users don’t give importance to choosing the right size of nails for nail guns. But it is a crucial factor before starting any woodworking project.

Here are some core reasons why nail gun nails sizes matter:

Proper Material Bonding

The correct nail size ensures that the nails are penetrated deeply to fasten the materials.

Prevents Material Damage

The wrong nail size damages the surface of the materials. Too long nails may split wood materials during work. It will hamper your project’s integrity and appearance.

Increases Structural Integrity

For heavy-duty projects like fencing, decking, roofing shingles, or framing, the right nail size ensures the structure can handle the load and last longer.

Prevent Misfire and Jamming

Wrong nail size causes accidental nail discharge and jamming. Use the right size of nails to avoid sudden misfiring and nail jamming.

Aesthetic Finish

The appropriate size of nails for projects like trim or furniture provides a professional-looking finish. Right nail size hardly leaves any nail holes on the materials.

Save Time and Resources

Right nail size minimizes the possibility of work errors, material waste, and work repetition. Thus, it will save you time and help you complete the work efficiently.

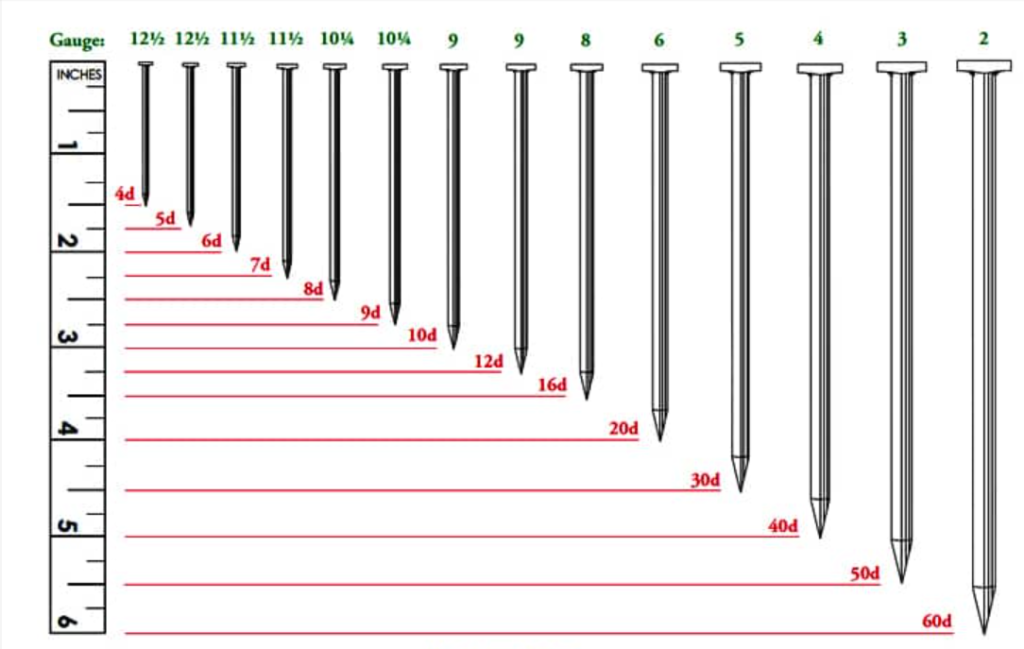

Industry Standards of Nail Sizes for Nail Gun

Here, I have discussed the industry standards of measuring nail size effectively. To understand nail sizes, you should first know about the commonly used measurements to determine nail size.

Penny Size

“Penny” refers to the standard unit of measurement for nails. The penny size is abbreviated as “d”. For example, 16 penny size nail is abbreviated as 16d nail. 16d nail is longer than an 8d nail.

Gauge

It is a commonly used unit of measurement that indicates nails’ diameter or thickness. Higher nail gauge sizes identify that the nails are thinner, with smaller nail gauge sizes, associated with thicker, stronger nails. For example, a 23 gauge pin nail is thinner than a 12 gauge nail size.

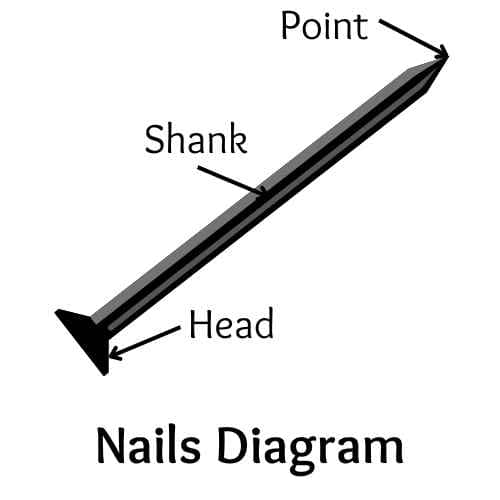

Shank Diameter

It is a measurement of nail thickness in inches. The shank of the nails defines the longer parts that get driven into the material, rather than the flat head nails.

Suppose, an 18 gauge brad nail’s shank diameter will be around 0.0475 inches (1.2 mm). A larger shank diameter provides strong holding power but might be the reason for splitting.

A smaller shank diameter is ideal for precision work. A smaller shank diameter is suitable for thin or fragile materials.

Shank Length

It indicates the length of the nails. Shank length is generally measured in inches (1-1/4″) or millimeters (32 mm).

Longer shank nails provide deeper penetration in thick or layered materials for strong holding power. The shorter one is suitable for thin and delicate materials.

Head Diameter

The nail head diameter is a measurement of the nail’s head. Head diameter is typically measured in inches. It determines the size of the nail head and its surface area.

A larger head diameter provides strong holding power. Large nail diameter is applicable where the nail head needs to prevent pull-through, such as roofing or drywall.

Smaller nail head diameter is especially used for aesthetic and professional finishing purposes. A small head diameter is less noticeable. They leave almost no wood holes that need to be covered with wood fillers.

Common Types of Nails for Nail Guns

Nail gun nails come with a wide range of nail types depending on the project and material type. Here, some popular nail types are listed:

Common Nails

Common nails are the most popular type of nails. They have smooth shanks. Common nails are perfect for structural works, repairing, and other uses for resistance.

Common nails are large flat-headed and made of steel or iron. The smooth shank common nails are ideal for supporting lateral loads where pullout resistance is a minor factor.

Box Nails

Box nails also have smooth shanks similar to common nails. But this type of nail has a slightly higher gauge. Because of the higher gauge, box nails provide less holding power and are suitable for thinner wood, trims, and other non-structural projects.

Concrete Nails

Concrete nails are thick, and used in heavy-duty projects like securing materials to concrete. These nails have a long shank and a large flat head.

Masonry Nails

Masonry nails are thicker and longer than concrete nails. These nails offer strong holding power that is enough for attaching materials to brick and stone.

Masonry nails also have large flat heads and long shank similar to concrete nails.

Annular & Threaded Nails

These nailers have threaded shanks. Threaded shanks offer additional grip. Annular or threaded nails come with enough pullout resistance and structural support.

Annular nails have strong holding power, that is superior for construction works, subflooring, and drywall replacement.

Brad Nails

Brad nails come with a diameter of 18 gauge. It is the most popular nail used by nail gun users. 18-gauge brad nails are shorter and thinner than 15 or 16-gauge finish nails.

They have smaller heads than 15 gauge finish nails. Suitable for very detailed trim works.

Finish Nails

Finish nails come with 15 and 16-gauge diameters, that is thinner and shorter than common nails. Finish nails are thicker than brad nails. These nails are used for trim work and smaller home furniture making.

Roofing Nails

Roofing nails come with a lower gauge diameter, compared to brad and finish nail gun nails. These nails have a large flat head and a longer shank. Roofing nails are perfect for roofing-related works like roof shingle installation.

What Size Nails for Nail Gun: Explained With Table of Charts

Here, I have divided the nail size chart into three major sections. The first one will define the popular nail gun nail sizes used by woodworkers. The second table of charts will indicate the box nail sizes. The last one will visualize the table of charts of annular and threaded nail sizes.

Table 1 – Common Nail Sizes Chart

Consider the below-mentioned common nail sizing chart:

| Penny Nails | Nail Gauge | Nail Shank Diameter | Nail Shank Length | Nail Head Diameter |

| 2D | 15 | 0.072 | 1” | 3/16″ |

| 2D | 14 | 0.083 | 1” | 13/64” |

| 3D | 14 | 0.083 | 1.25″ | 13/64” |

| 4D | 12 | 0.109 | 1.5” | 1/4″ |

| 5D | 12 | 0.109 | 1.75″ | 1/4″ |

| 6D | 11 | 0.12 | 2” | 17/64″ |

| 8D | 10 | 0.134 | 2.5″ | 9/32″ |

| 10D | 9 | 0.148 | 3” | 5/16″ |

| 12D | 9 | 0.148 | 3.25″ | 5/16″ |

| 16D | 8 | 0.165 | 3.5″ | 11/32” |

| 20D | 6 | 0.203 | 4″ | 13/32″ |

| 30D | 5 | 0.22 | 4.5″ | 7/16” |

| 40D | 4 | 0.238 | 5” | 15/32″ |

| 60D | 4 | 0.238 | 6” | 17/32″ |

Table 2 – Box Nail Sizes Chart

Consider the below-mentioned box nail sizing chart. It will help you figure out the perfect size of box nail for your upcoming project.

| Penny Nails | Nail Gauge | Nail Shank Diameter | Nail Shank Length |

| 3D | 14-1/2 | 0.076 | 1.25″ |

| 4D | 14 | 0.080 | 1.5″ |

| 5D | 14 | 0.080 | 1.75″ |

| 6D | 12-1/2 | 0.098 | 2” |

| 7D | 12-1/2 | 0.098 | 2.25″ |

| 8D | 11-1/2 | 0.113 | 2.5″ |

| 10D | 10-1/2 | 0.128 | 3″ |

| 16D | 10 | 0.135 | 3.5″ |

| 20D | 9 | 0.148 | 4″ |

Table 3 – Annular & Threaded Nail Sizes Chart

Consider the below listed annular and threaded nail sizing chart. It will assist you in selecting the right annular nail for your next project.

| Penny Nails | Nail Shank Diameter | Nail Shank Length |

| 6D | 0.12 | 2″ |

| 8D | 0.12 | 2.5″ |

| 10D | 0.135 | 3” |

| 12D | 0.135 | 3.25″ |

| 16D | 0.148 | 3.5″ |

| 20D | 0.177 | 4” |

| 30D | 0.177 | 4.5” |

| 40D | 0.177 | 5” |

| 50D | 0.177 | 5.5″ |

| 60D | 0.177 | 6” |

| 70D | 0.207 | 7” |

| 80D | 0.207 | 8” |

| 90D | 0.207 | 9” |

Nail Gun Nails Sizes Chart by Project Type

Here, I have tried to simplify selecting the right nail size for your nail gun, based on your project type. Hopefully, this project-based nail size chart will help you choose the best nail for your project.

| Types of Projects | Nails Sizes | Nails Gauge |

| Framing | 3 ¼ inches (16d nails) | 8-10 |

| Trim and Molding | 1 ¼ to 2 ½ inches | 15-16 |

| Cabinetry & Furniture | 5/8 to 2 inches | 18 |

| Siding Installation | 1 ¼ to 2 ½ inches | 6-9 |

| Decking & Outdoor | 2 ½ to 3 inches | 10-12 |

| Flooring | 1 ½ to 2 inches | 16-18 |

| Upholstery | ¼ to ⅝ inch (Staples) | 22-24 |

| Concrete & Steel | ¾ to 2 ½ inches | Heavy-duty |

| Crafts & Hobbies | 3/8 to 1 inch | 23 |

Nail Gun Nails Sizes Chart by Material Type

Here is a list of the right sizes of nails based on the material type. It will help you determine the right size of nails depending on your materials’ surface types.

| Material Type | Nail Size | Nail Gauge | Nail Type |

| Softwood (Pine) | 2 to 3 ¼ inches | 8–10 | Common Nails |

| Hardwood (Oak) | 1 ½ to 2 ½ inches | 15–16 | Finish Nails |

| MDF or Particle Board | 1 ¼ to 2 inches | 18 | Brad Nails |

| Vinyl Siding | 1 ½ to 2 ½ inches | 6–9 | Galvanized Nails |

| Pressure-Treated Wood | 2 ½ to 3 inches | 10–12 | Stainless Steel Nails |

| Concrete and Steel | ¾ to 2 ½ inches | Heavy-duty nails | Concrete Nails |

| Fabric and Upholstery | ¼ to ⅝ inch (Staples) | 22–23 | Staples |

| Plywood or OSB | 1 ½ to 2 ½ inches | 15–16 or 18 | Finish or Brad Nails |

| Thin Trim or Moldings | 5/8 to 1 inch | 23 | Pin Nails |

| Roof Shingles | 1 – 1 ¾ inches | 12 Gauge | Roofing Nails |

How to Calculate Nail Gun Nails Sizes: With Quick Formula

There is a simple formula to figure out the appropriate nail size based on the type of materials and nail guns.

The quick formula to calculate nail length is:

Length of Nails = Thickness of Top Material + (Base Material Thickness ×1.5)

Explanation:

- Top Material Thickness: Thickness of the material like vinyl, trim, plywood, etc.

- Base Material Thickness: The base thickness of the material where the nails will be driven such as studs, subfloor, etc.

- 1.5 (The Multiplier): Indicates the nail will penetrate the materials at least 1.5 times its thickness. It ensures a secure hold of the nails.

Some real-life examples of calculating nails:

Example 1: (Installing Trim)

Suppose,

Top Material Thickness: 0.5 inch

Base Material Thickness: 1 inch

Calculation: Nail Length = 0.5 + (1 × 1.5)

= 2 inches

Then nail length is 2 inches.

Example 2: (Framing 2 x 4)

Suppose,

Top Material Thickness: 1.5 inches

Base Material Thickness: 1.5 inches

Calculation: Nail Length = 1.5 + (1.5 × 1.5)

= 3.75 inches

Then the nail length is 3.75 inches.

Example 3: (Siding Installation)

Suppose,

Top Material Thickness: ¾ inch

Base Material Thickness: 1 inch

Calculation: Nail Length = 0.75 + (1 × 1.5)

= 2.25 inches

Then the nail length is 2.25 inches.

Example 4: (Fencing Pickets)

Suppose,

Top Material Thickness: 0.75 inch

Base Material Thickness: 1.5 inches

Calculation: Nail Length = 0.75 + (1.5 × 1.5)

= 03 inches

Then the nail length is 03 inches.

Example 5: (Decking)

Suppose,

Top Material Thickness: 1 inch

Base Material Thickness: 1.5 inches

Calculation: Nail Length = 1 + (1.5 × 1.5)

= 3.25 inches

Then the nail length is 3.25 inches.

Example 6: (Subflooring)

Suppose,

Top Material Thickness: 0.75 inch

Base Material Thickness: 1.5 inches

Calculation: Nail Length = 0.75 + (1.5 × 1.5)

= 03

Then the nail length is 03 inches.

Example 7: (Installing Plywood)

Suppose,

Top Material Thickness: 0.375 inch

Base Material Thickness: 0.75 inch

Calculation: Nail Length = 0.375 + (0.75 × 1.5)

= 1.5

Then the nail length is 1.5 inches.

How to Choose The Right Nail Size for Your Project?

Selecting the right size of nails is essential for any nail gun project. Whether you are a professional nail gun user or a beginner, picking up the right size of nails becomes a big challenge. Proper and accurate nails will reduce half of your job instantly.

To select the right nail size, first, you need to figure out your project type, material type, and nail gun type. While you are determined with these 3 things, then you can go for the above-mentioned table of charts to pick up the correct nail size easily and more efficiently.

Even then, if you are confused then you can easily apply the above-mentioned quick formula. I hope it will be helpful and effective for you.

My Final Words

So, choose your nail gun nails wisely by dint of these processes and formulas. These simple processes will eradicate all of your confusion and work errors regarding proper nail choosing.

FAQs

1. Are there any differences between nails and screws?

Ans: Nails and screws are both effective fasteners to hold materials together. But there are some subtle differences between them. They have differences in some key aspects such as design, strength, appearance, size, versatility, installation, etc.

2. Can you use different-sized nails in a nail gun?

Ans: No, unfortunately, you can not use different-sized nails in nail guns. The nail guns can operate the nails for which it is built. The nail size must be similar to the design of the nail gun. The length of the nails can vary.

3. What size nail gun for 8d nails?

Ans: A framing nail gun can be the most suitable tool for operating 8d nails. 8d nails are generally 2.5 inches long, and 0.134 inches thick. These nails are popular for framing projects, sheathing works, and general construction projects.

4. What size nails do framing nail guns use?

Ans: Framing nail guns typically use 11-12 gauge nails. Framing nailers come with different angles and the nail sizes should match the nailer’s angle.

5. Are nail sizes universal?

Ans: No, nail sizes of nail guns are not universal. Do not rely on sizes from other brands or models.