A roofing nail gun is not your average nail gun! If you plan to use something other than a roofing nailer to drive nails into roofing related projects, the nails won’t hold the shingles and will damage the project.

This nail gun is an effective tool for heavy-duty projects. We need to maintain it properly. Therefore, users should have enough knowledge regarding this powerful fastening tool.

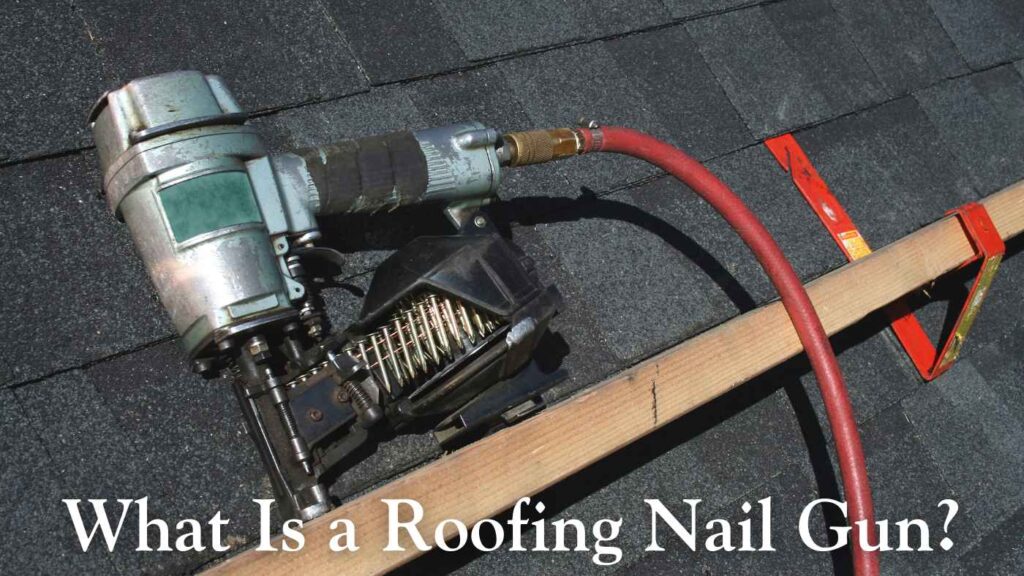

What Is a Roofing Nail Gun?

A roofing nail gun is a powerful nailing tool that drives nails to fasten roofing materials such as shingles, underlayment, and insulation, to a roof deck.

Roofing nailers are designed for speed, precision, and durability to handle the unique challenges of roofing projects.

The nail size range for roofing nailers’ nails is usually range between 1 inch and 2 inches in length.

The key components of this nail gun are coil style magazine, depth adjustment mechanism, and trigger mechanism.

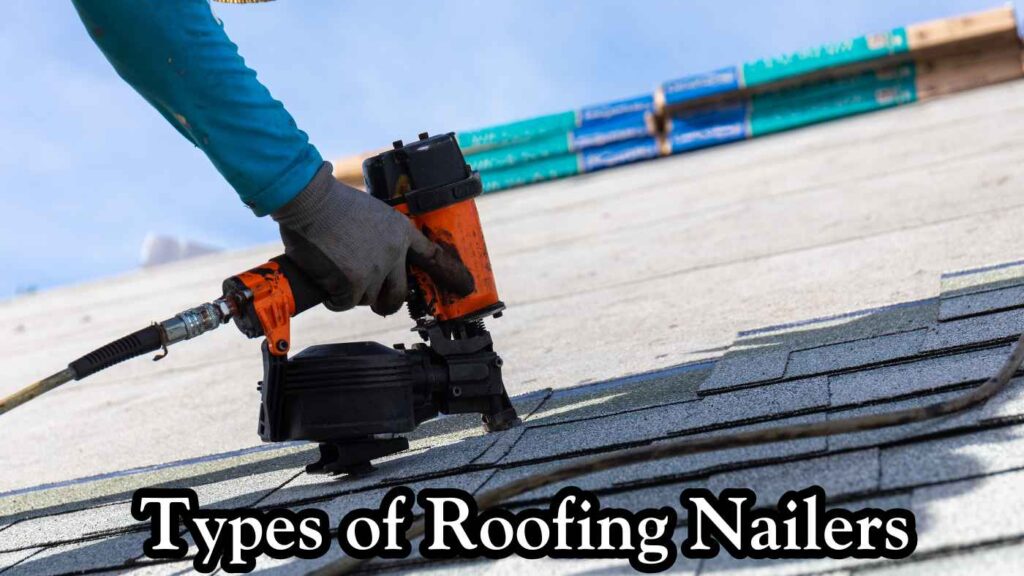

Types of Roofing Nailers

There are three main types of roofing nailer guns based on the power sources. They are coil roofing nail guns, pneumatic roofing nail guns, and cordless roofing nail guns.

Coil Roofing Nail Guns

These roofing nail guns use coil style nail magazines. that hold a large number of nails. They can hold more than 120 nails in the magazine.

They are slightly heavier while loaded fully and require regular maintenance for jamming.

Pneumatic Roofing Nail Guns

These nail guns use air compressors and hoses to drive nails. They’re the most common and efficient version in the realm of nail guns.

They provide high power and consistency. A pneumatic roofing nail gun is suitable for heavy duty and continuous use.

Cordless Roofing Nail Guns

Cordless powered means battery powered roofing nailers. These nailers need a rechargeable battery to operate smoothly. They don’t require cords or compressors.

These types of roofing nailers offer greater mobility and portability. They deliver limited power compared to pneumatic roofing nailing guns.

Key Features of Roofing Nailing Gun

Here, we will talk about the core specifications of roofing nailer guns:

Nail Magazine System

These roofing nailers come with 2 nail magazine mechanisms. One is coil style and the other one is strip style.

Coil style magazines hold a high volume of nails that reduces frequent nail loading during longer projects. Nowadays, strip magazines are used rarely.

Nail Triggering Mechanism

Roofing nailers come with 2 types of trigger mechanisms. One is a contact trigger and the other one is a sequential trigger.

Contact trigger fires nails when the nose is pressed. In contrast, a sequential trigger requires both the trigger pull and nose contact.

Adjustable Depth Control

This flexible feature allows you to control how far the nails will be driven into the material.

This feature eliminates nail over driving and under driving. It also ensures consistent nailing for various roofing materials.

Ergonomic Design

The ergonomic design means a comfortable grip on the hands. It reduces hand fatigue issues while doing heavy duty projects.

Since roofing jobs are labor-intensive, an ergonomic design reduces hand strain and increases productivity.

Exhaust System

Directs air away from the user. This system safe you from dust and debris.

Roofing Nails Compatibility

Roofing nail gun nails can handle nails with wide heads for attaching shingles.

Compatibility ensures that the nail gun can be used for various roofing uses.

Anti-Jamming Mechanism

The anti-jamming mechanism in roofing nailers eliminates nail jams during any job. It ensures smooth and uninterrupted operation during large projects.

Adjustable Roofing Shingle Guide

Adjustable roofing shingles help you maintain consistent nail spacing and positioning for roofing shingles.

It helps you keep accuracy and gears up the shingle installation process.

Advantages & Disadvantages of Using a Roofing Nailer Gun

We know that a roofing nailer is an effective and efficient tool.

But likewise every tool, this nail gun comes with some benefits and limitations.

Let’s see the advantages and drawbacks of using a roofing nailer gun:

Advantages

Speed and Efficiency

Roofing nailers speed up the process compared to manual nailing methods like hammering. It offers faster completion of your roofing installation tasks.

Consistency

These nailers can drive nails with uniform pressure and depth settings. It provides a more professional and beautiful outlook.

Less Physical Effort

If you use a roofing nail gun in your roofing related projects, will reduce the physical effort required for manual hammering.

Precision

Many roofing nailers are featured with depth customization settings to avoid overdriving or underdriving nails. It results in a precise finish.

Versatility

These nail guns are enough versatile to finish roofing projects.

They can handle different nail sizes and materials for various roofing tasks like asphalt shingles, wood shingles, and siding.

Safety Features

Modern roofing nailer guns have upgraded safety mechanisms like sequential triggers, safety contact tips, etc.

Disadvantages

Initial Cost

Roofing gun nailers are more expensive compared to other manual tools. The pneumatic version of roofing nailers is more costly than other versions of roof nail guns.

Maintenance Requirements

Regular maintenance like cleaning, lubrication, and part replacement is required to keep the tool smooth and ready to use. Pneumatic roofing nail guns need regular oiling.

User Efficiency

This nail gun is not perfect for beginners and hobbyists. To operate them efficiently someone needs proper training. It requires some training and practice to operate efficiently and safely.

Noise Levels

Noise levels vary based on the type and brand. A pneumatic roofing nailer produces noise levels between 90 to 100 decibels (dB) or more. Air powered roofing nailers produce more noise than other types.

Cordless or battery-powered roofing nailers produce noise in the range of 85-95 dB and electric roofing nailers produce noise in the range of 80-90 dB.

Weight & Bulkiness

Roofing nailer guns are bulky and heavy in weight. Their weight range between 5.5 pounds to 8 pounds. But it can vary based on the model and manufactured brands.

Nail Gun for Roofing Shingles & Other Uses

We know roofing nail guns are best for installing roofing shingles commercially and residentially. Besides roof shingles, they are used in various applications.

Let’s breakdown them:

Underlayment Installation

Roofing nail guns are used to secure the underlayment to the roof deck. This means the layer of material is placed under the shingles for protection against moisture.

The nails used in this task are similar to roofing nails but slightly smaller. Underlayment installation is an essential part of the roofing system.

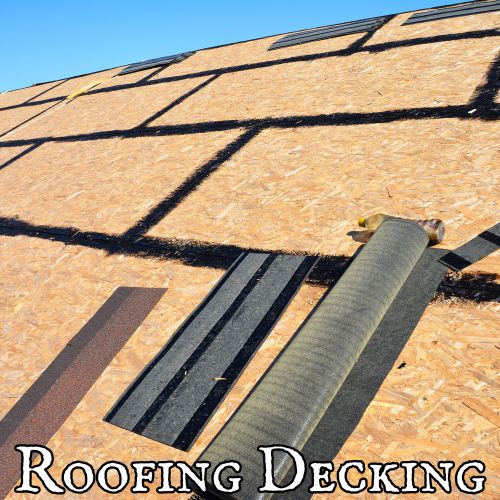

Roof Decking

Roof decking works as the foundation for roofing materials like shingles or tiles. You can use roofing gun nails to nail down roof decking much faster and more efficiently.

These nails are perfect for securing decking tightly to the roof trusses.

Installing Roof Vents

Roofing gun nailers are also used to install roof vents and flashing. It is a vital tool for maintaining proper airflow and preventing water damage.

Roofing nails ensure the flashing and vents are installed tightly and securely. Which is a critical job for the roof’s longevity. It can hold the components firmly in place, preventing shifting or loosening over time.

Siding Installation

Roofing nailer guns can be used for some lightweight siding installation.

They can also be effective for light duty siding installation, particularly when you’re working with softwood panels or thin vinyl siding.

Insulation & Vapor

For certain insulation or vapor barrier projects, a roofing nailer gun is effective for securing plastic or similar materials to underlying structures.

The roofing nails are large enough to hold insulation sheets in place on various materials.

Fencing

In some cases, you can use roofing nailers for wood fencing. Roofing nailers musically come with shorter nails that range between 1-2 inches.

If your roofing nailer is compatible with long nails like 2-3 inches, then you can go for it. Because in 2 X 4 fencing projects, the nails should penetrate the wood.

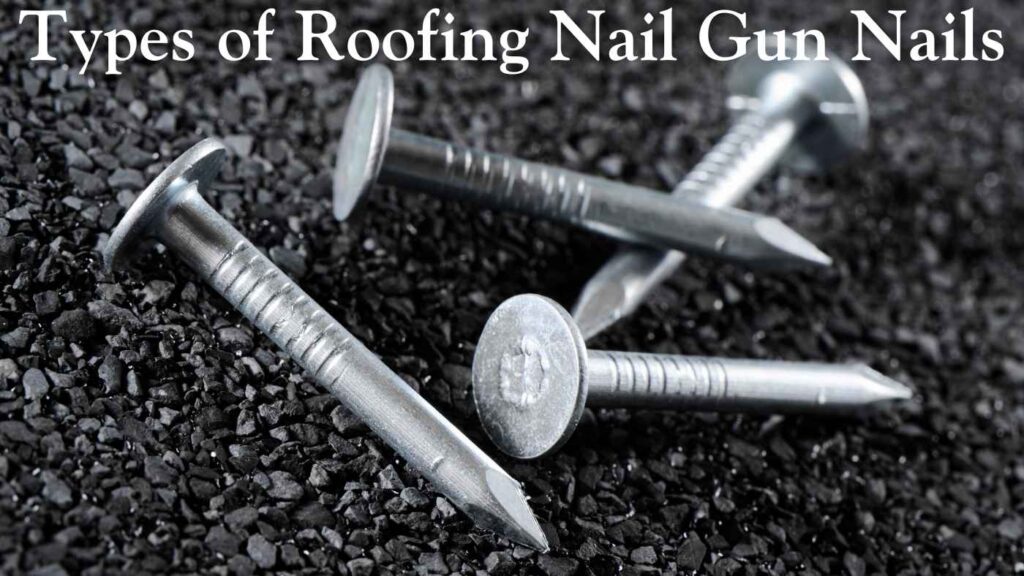

Types of Roofing Nail Gun Nails

There are several types of roofing nails. They are designed for specific materials and purposes.

Here are some types of roofing nails:

Smooth Shank Roofing Nails

This type of roofing nail comes with smooth, and straight shafts with no added texture. They are best for light roofing materials like asphalt shingles.

Ring Shank Roofing Nails

Ring shank roofing nails usually have a series of rings or grooves around the shaft.

The ring shanks deliver better holding power. They are used for medium weight asphalt shingles or wood shakes to enhance grip.

Screw Shank Roofing Nails

These nails have thread-like spirals along the shaft. You can use these nails to ensure superior holding power.

Barbed Shank Roofing Nails

Barbed shank nails are featured with a barbed shaft with grooves.

It will help you prevent the nail from pulling out once driven in. They are mostly applied in situations where extra resistance to removal is required.

Plastic Cap Roofing Nails

Plastic cap nails have a large plastic or metal cap at the head.

Plastic or metal headed nails are used for securing roofing materials like underlayment or felt paper.

The cap distributes the pressure needed to the roofing material.

Aluminum Roofing Nails

You can use aluminum roofing nails in coastal areas or places with high humidity. Because these nails are made of lightweight and corrosion resistant aluminum.

Galvanized Roofing Nails

These nails are coated with zinc. They help you avoid rusting and corrosion.

They are widely used for asphalt shingles, wood shakes, and other types of roofing materials for better longevity.

Size of Nails for Roofing

Roofing nails typically range from 1 inch to 2 inches in length with a shank diameter of 11-12 gauge (Approx. 0.12 inches or 3 mm).

Roofing nails have a flat, broad head, that range within 3/8 inch (9.5 mm) in diameter (Approx.)

Whenever you go for a roofing task you need to choose the right size of nails. The right size of nails will deliver you a better output.

Therefore, to select the right size of nails based on your project and materials you should have vast knowledge of every aspect of nail sizes for roofing.

Let’s dive into the deep to explore the nail sizes and their compatibility:

Length of Roofing Nails

The lengths of roofing nails are 1, 1 ¼, 1 ½, 1 ¾, and 2 inches. They are dedicated to specific tasks and materials.

1-inch Nails

They are best for thin materials like roofing felt or lightweight asphalt shingles. You can use them for attaching underlayment.

For example, synthetic material. This size of nails can secure single layer shingles.

It will be wise to ensure the nails penetrate the sheathing by at least ¾ of an inch.

1 ¼-inch roofing nails

You can use them for installing standard three tab shingles or architectural shingles over standard sheathing.

This is the most used size for asphalt shingle installations. These size roof nails deliver sufficient length for proper penetration into the sheathing without excessive expansion.

1 ½-inch roofing nails

These size nails are suitable for thicker shingles or overlapping layers. They are used for Installing architectural shingles. These shingles are thicker than standard three-tab shingles.

if local building codes allow, then you can use them to secure shingles over existing layers during reroofing. They are enough long to penetrate through multiple layers while installing shingles.

1 ¾-inch roofing nails

These inch roofing nail gun nails are suitable for additional layering. They are mostly useful for projects where thicker underlayment or additional layering is required.

You can apply this size for reroofing projects with two or more layers of shingles. Moreover, you can install wooden shakes or thicker synthetic shingles with this size of nails.

2-inch roofing nail

They are considered for very thick materials or dense sheathing. If you have any running project that requires maximum penetration you can try this size.

maximum penetration projects mean thicker wooden shakes or layered roofing.

2 inch roofing nails are also used for attaching shingles over thick insulation boards. They are necessary for heavy-duty roofing projects but sometimes it is overkill for most asphalt shingles.

Gauge of Roofing Nails

The “gauge” word is synonymous with the thickness of the nails. The gauge of roofing nails are widely available in 10, 11, and 12 gauge.

We know that the lower the gauge number, the thicker the nail. These 3 gauge nails are widely permitted as building codes.

10 Gauge Roofing Nails

They are thicker than 11 or 12 gauge. 10 gauge means 0.135 inches of thickness (approx.).

They are best for Installing thicker roofing materials, such as tiles. Thicker gauges provide more resistance to bending in heavy duty applications.

11 Gauge Roofing Nails

12 gauge means 0.120 inches of thickness (approx.). That is medium thickness. You can use them for three tab and architectural shingles.

They are standard for most roofing projects. This size of nails can keep a balance between strength and ease of penetration.

12 Gauge Roofing Nails

12 gauge means 0.105 inches of thickness (approx.). They are used for Installing roofing felt or synthetic underlayment.

If you plan for any roofing projects where thin or delicate materials will be used, then you can use this size of nails. They are easier to drive into materials.

Roofing Nails Gun Safety & Maintenance Tips

Roofing Nail Gun Safety Tips

While operating a roofing nail gun, you should abide by the safety features. If you can’t ensure safety checklists during roofing works, then your project may turn into a hazardous project.

Let’s meet some roofing nail gun safety tips:

- Wear proper safety gear like safety goggles, ear protection (earplugs or earmuffs), non-slip footwear, and hand gloves.

- Inspect the working location to ensure the roofing surface is stable and dry. Avoid working in wet, or icy weather to reduce slip risks.

- Check if there are any chances of tripping hazards like extension cords or loose shingles.

- Use full sequential trigger

- Keep your hands and body away from the nail discharging area.

Roofing Nail Gun Maintenance Tips

Yes, a roofing nail gun is an effective tool. It gives you the utmost results in every roofing project. But it is like a responsibility to keep your nail gun in tip top shape.

If you keep your nail guns in tip top shape, then it will provide you with smooth operation as well as greater longevity.

To keep your nail gun in better condition you should have some ideas on tool maintenance.

Let’s meet some roofing nail gun maintenance tips:

- First, establish a nail gun work procedure for checking if your nail guns are functioning properly every day. Procedures help you organize your tasks properly and safely.

- Clean and lubricate the nail gun regularly. Oil the pneumatic version of roofing nailers.

- Tighten Loose Screws and Bolts.

- Ensure the tool is free from cracks.

- To avoid jamming always try to use the correct size of nails.

- Store the nail guns in a dry, secure location. Never forget to disconnect the air compressor or battery when not in use.

Alternatives to Roofing Nail Guns

For roofing projects, a roofing nail gun is the best choice. You can’t think of a roofing project without roofing nailers.

However, in some cases, if you don’t have access to a roofing nailer, then you can go for other alternatives for installing roofing materials. But it is sure, these alternatives can not replace a roofing nailer gun.

Here are the most common alternatives:

Hammers

The traditional alternative to a roofing nail gun is a hammer. This is a manual nailing method. Hammer requires more time and physical effort.

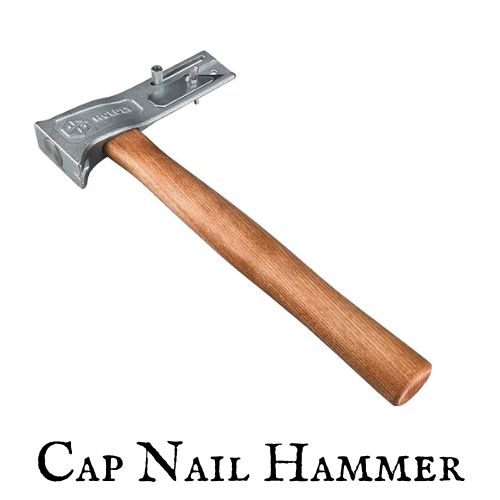

Cap Nail Hammer

A cap nail hammer is a specialized tool used to drive nails with plastic or metal caps. Plastic or metal nails are used in roofing nail guns.

Staple Gun

A manual or pneumatic staple gun can be used for specific roofing tasks, but it is not suitable for shingles because staples can tear through the material.

Screwdriver or Drill

You can use a screwdriver or power drill with roofing screws for certain roofing materials like metal panels. But they can’t replace a nail gun. They are slower than roofing nailers.

Adhesives or Roofing Cement

In some cases, roofing adhesives or cement can be used to secure shingles temporarily. However, this is not a primary fastening method. You can just use them for some small repairs.

Conclusion

A Roofing nail gun is a game changer for installing roofing shingles.

There are no proper alternatives that can fully replace a roofing nailer gun. If you are a professional roofer, then a roofing nail gun is the best option.

From speed and precision to safety and durability, this roofing nailing gun can save you time, money, and frustration.

FAQs

1. How many roof nails per square?

Ans: In the case of standard asphalt shingles, you will need 4 nails per shingle. With about 80 shingles per square (100 sq. ft.), this equals 320 nails per square.

In high wind zones, require 6 nails per shingle. This means totaling 480 nails per square.

2. How to tarp a roof without nails?

Ans: To tarp a roof without nails, at first, use a large tarp that extends past the roof edges, secure it with rope, bungee cords, or roof clips, and weigh down the edges with bricks or sandbags to prevent it from blowing away.

3. Can you use roofing nails for siding?

Ans: No, it is not recommended to use roofing nails for siding. But in some cases, you can use roof nails for lightweight siding like vinyl siding.

Roofing nails are used for thinner materials like shingles while siding work requires longer nails for better hold.

4. Can I use siding nails in a roofing gun?

Ans: No, you can’t use siding nails in a roofing nailing gun. Roofing nailers hold shorter nails with wide heads while siding nails are longer and thinner for better penetration.

Therefore, siding nails in a roofing gun can cause improper installation and potential damage to the roof nail gun.

5. Can you use roofing nails for vinyl siding?

Ans: Vinyl is generally considered a thinner material compared to many other siding options like wood or fiber cement.

Therefore, you can use roofing nails for vinyl siding in some circumstances. But it is not 100% recommended.

6. Are roof nail pops covered by insurance?

Ans: Nail pops might be a result of normal wear and tear or improper installation of roof shingles. Therefore, roof nail pops may not be covered by homeowners’ insurance.

Insurance providers cover insurance for damages resulting from sudden, or accidental events like firings, or storms.

As nail pops are considered a maintenance issue, it won’t cover any insurance criteria. However, if the situation is not similar to this, then you can contact an insurance company.